Different Cooling Technologies Used in Industrial Cooling Systems

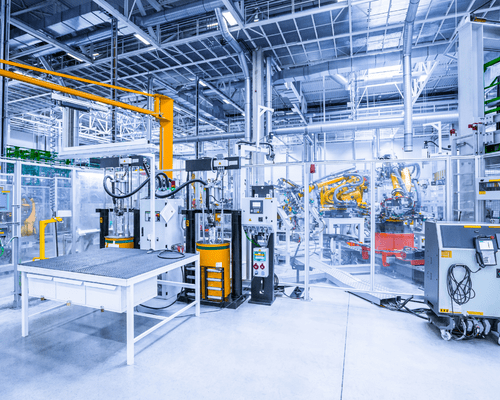

In industrial enterprises, it is vital to keep production processes and equipment within the desired temperature range. For this purpose, industrial cooling systems are used. Different cooling technologies used in industrial cooling systems may vary according to the specific needs and application requirements of the enterprises. This article will provide information about some of the different cooling technologies commonly used in industrial cooling systems.

Vapor Compression Cooling Systems:

Vapor compression refrigeration systems are one of the most widely used technologies for industrial refrigeration. These systems include a compressor, a condenser, an expansion valve, and an evaporator. Its working principle is to increase the temperature of a refrigerant (usually a gas) by compressing it and then cooling it by removing the heat by the evaporation process. Vapor compression refrigeration systems have a wide range of applications in industrial facilities.

Absorption Cooling Systems:

Absorption cooling systems are a cooling technology used as an alternative to vapor compression systems. In these systems, a heat source (usually steam or hot water) is needed for a refrigerant to evaporate. This evaporation process allows the refrigerant to absorb heat and then react with the absorbent in an absorber. As a result of this reaction, the evaporation temperature of the refrigerant drops and the refrigerant vapor condenses in the condenser. Since absorption cooling systems provide advantages in terms of energy efficiency, they are used especially in industrial facilities for energy saving purposes.

Cooling Tower Systems:

Cooling tower systems are a technology used to meet the large-scale cooling needs used in industrial facilities. These systems are generally used for water cooling operation. A water circuit is created, which is used to cool heat-generating equipment (eg evaporators, cooling machines). The heat is removed by evaporation by directing the water to the cooling tower. Cooling tower systems provide effective cooling when used in large-scale industrial facilities.

Vortex Cooling Technology:

Vortex cooling technology is a cooling method without compressors and moving parts. In this technology, a high-speed rotating air stream is created and as a result, the temperature of the compressed gas decreases. Vortex cooling devices are used in industrial plants to meet small-scale cooling needs. It is especially effective in cooling electronic equipment and provides energy efficiency.

Peltier Cooling Technology:

Peltier cooling technology is a method that provides cooling using the thermoelectric effect. In this technology, a Peltier device (thermoelectric cooling device) is powered by electric current. This device uses the temperature difference between the semiconductor materials to cool one surface and heat the other surface. Peltier cooling technology is used for small-scale cooling needs and is suitable for portable devices.

Different cooling technologies used in industrial cooling systems vary according to the specific needs and application requirements of businesses. Vapor compression systems, absorption systems, and cooling tower systems are common technologies used to meet a wide range of industrial cooling needs.

Vapor compression systems have a wide range of applications and are a widely used technology with high energy efficiency. Absorption systems, on the other hand, offer an alternative for energy saving. Cooling tower systems are used in large industrial facilities and are effective in water cooling operations. Vortex cooling technology has a structure that does not contain compressors and moving parts and provides energy efficiency. Peltier cooling technology is used for small-scale cooling needs and is a suitable option for portable devices.

Industrial cooling systems are vital for businesses to optimize their production processes, increase energy efficiency and maintain product quality. Choosing the right cooling technology is an important factor for businesses to achieve these goals. By evaluating the advantages and disadvantages of each technology, businesses can obtain an efficient and reliable cooling solution with the most suitable cooling system for their needs.

Get an Offer Contact UsReferences

As Alfa Proje, we serve each of our projects with years of experience and passion.

ASSEMBLY, MAINTENANCE AND REPAIR

ALFA PROJE DIŞ TİCARET INC. designs the processes specially according to your special demands and ensures the assembly of your projects by authorized and expert technical teams. Our company is ready to provide 24/7 maintenance and repair support with its expert technical service in Turkey and abroad for your projects.